HOME > MACHINES > EXCAVATORS

835H

DESIGNED TO

WORK HARDER,

FOR LONGER

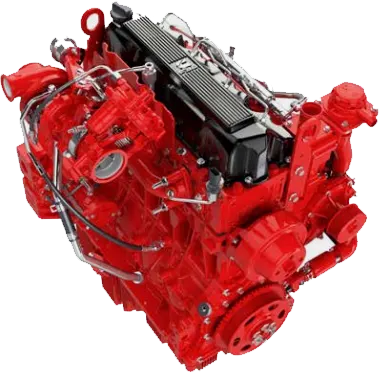

Engine

Cummins B4.5

EU Stage V

EU Stage V

Net Power

106 kW (142 hp / 144 ps)

@ 2,200 rpm

@ 2,200 rpm

Weight

12,725 kg (28,054 lbs)

Bucket Capacity

1.9 m3 (2.5 yd³)

AWARD WINNING DESIGN

Our UK-based design team has invested thousands of man hours to really understand how our machines are used every day. This insight shapes our innovative approach to product design. Our design team recently won a prestigious Red Dot Award for our D-Series Grader and all our products this award-winning design DNA

JOBSITE ADAPTABILITY

To ensure real return on investment you demand machines that can quickly adapt to any situation on the jobsite and handle multiple jobs with speed and precision. Our new 835H wheel loader combined with our perfectly matched quick coupler and attachments, create the ultimate in multi-tools. Here is a selection of key benefits, common to both of our new machines.

Our new wheel loaders match their power to the job with world-class, versatile engines, designed to maximize torque and deliver more power and breakout force at lower engine speeds.

The new 4-speed ZF power shift transmission, including torque converter, cleverly adapts to any situation, ensuring the maximum transfer of power to improve performance and fuel efficiency.

LiuGong’s new-generation advanced hydraulic system adapts itself to any job organizing the mechanical, electrical and hydraulic systems to work in perfect harmony. Power is supplied only as needed, achieving optimum operation, whatever the application.

Multiple tasks require total control. The kick-down and forward/reverse buttons are conveniently located on the loader joystick, putting absolute control right where it belongs - in the operator’s hands.

Optimized Z-Bar geometry further improves the adaptability of our machines enhancing bucket breakout force, loading stability, speed and operator visibility.

For the ultimate in traction and manoeuvrability, you can rely on our limited-slip differential axles. They automatically deliver power to the wheels making turning easier, reducing tire wear and maximizing bucket-filling performance.

The chassis frame is the backbone of the machine, so it’s got to be tough. Our rigorous design and testing regime has delivered a chassis capable of absorbing all the forces and pressures of the toughest environments and most demanding jobs. Year after year, our chassis stays strong, protecting the driveline, your operator and your profitability.

Jobsite adaptability is about perfectly matching the machine to a wide range of attachments. We’ve created a versatile tool that will maximize productivity and return on investment.

When it comes to safety our cabs are second to none. ROPS and FOPS safeguard your operator, but we’ve gone further by enhancing visibility to create a safer environment inside and outside the cab.

POWERED TO PERFORM

Jobsite adaptability is about giving you the power to get more productivity from your machine, but for less cost and less environmental impact.

At the heart of our brand new 835H beats world-leading engine technology from Cummins. The engine has been carefully chosen to help deliver operational versatility, reduce cost and to comply with the latest environmental legislation.

The engine uses a precise, high pressure common-rail fuel injection system, smart wastegate turbo and air–to-air intercooler combining to deliver optimal performance whatever the task. Integrated post-processing system(DOC+DPF+SCR) achieves Stage V emissions regulations.

But we go even further to reduce environmental impact and boost your bottom line.

Our engine is optimized for rapid throttle response, getting the job done fast, but not at the expense of the environment. Fuel consumption and emission are significantly reduced with Intelligent Auto-Idle Speed Control. This smart function matches the engine speed and RPM to the task, automatically switching to idle speed between actions. Tests indicate that a significant amount of fuel (2-3 L) can be saved on a typical 8 hour shift.

Our engine may be green but they don’t compromise on toughness. Endurance testing exposes it to over 30,000 hours of relentless testing, proving that our machines really do have the power to perform, shift after shift.

The engine uses a precise, high pressure common-rail fuel injection system, smart wastegate turbo and air–to-air intercooler combining to deliver optimal performance whatever the task. Integrated post-processing system(DOC+DPF+SCR) achieves Stage V emissions regulations.

But we go even further to reduce environmental impact and boost your bottom line.

Our engine is optimized for rapid throttle response, getting the job done fast, but not at the expense of the environment. Fuel consumption and emission are significantly reduced with Intelligent Auto-Idle Speed Control. This smart function matches the engine speed and RPM to the task, automatically switching to idle speed between actions. Tests indicate that a significant amount of fuel (2-3 L) can be saved on a typical 8 hour shift.

Our engine may be green but they don’t compromise on toughness. Endurance testing exposes it to over 30,000 hours of relentless testing, proving that our machines really do have the power to perform, shift after shift.

Inefficient engine cooling has a negative effect on fuel economy and emissions. We have focused our design experience on greatly improving the engine cooling system. The new 6mm hexagon grill improves ventilation while a new reversible hydraulic fan, increases cooling efficiency with the flick of a button.

4-cylinder, 4.5 liter, turbocharged, common-rail Net power rating of 106 kW (142 hp) @ 2,200 rpm.

Our new 835H offers 4 speeds forward (4F) and 3 speeds reverse (3R).

The new 4-speed ZF power shift transmission, , cleverly adapts to any situation, ensuring the maximum transfer of power to the transmission for improved performance and fuel efficiency.

Optimized gear ratios and auto-shift functionality provide faster acceleration and faster cycle times, regardless of the application. Kick-down and Forward/Reverse buttons are conveniently located on the loader joystick for efficient operator/machine interface, further reducing cycle times and improving production and efficiency.

The new 4-speed ZF power shift transmission, , cleverly adapts to any situation, ensuring the maximum transfer of power to the transmission for improved performance and fuel efficiency.

Optimized gear ratios and auto-shift functionality provide faster acceleration and faster cycle times, regardless of the application. Kick-down and Forward/Reverse buttons are conveniently located on the loader joystick for efficient operator/machine interface, further reducing cycle times and improving production and efficiency.

500,000

MACHINES

DELIVERED

SHARING OUR CUSTOMERS’ SUCCESS

No matter what we say or how passionately we argue our case, ultimately jobsite adaptability comes down to one unavoidable question.

Can our machines really cut it in the real world?

Our answer?

Ask the satisfied owners of the 500,000 LiuGong wheel loaders already delivered. Their trust in our knowledge, their satisfaction in our product and their loyalty, have made LiuGong one of the world’s largest wheel loader manufacturers.

Don’t take our word… take theirs.

TOUGH RESEARCH AND TESTING

Finding tougher, smarter, safer and more cost-effective ways of working matters to you. It matters to us too. Our new Global Research & Development Centre is a great example of this customer focused approach. We’ve established an international team of industry experts, backed up with the latest world-class technology, all focused on delivering greater value to you.

DESIGNED TO GET MORE DONE

Jobsite adaptability is about giving you more options to take on multiple tasks and to achieve higher return on your investment.

Our ISO 23727 compliant quick coupler lives up to its name and turns your wheel loader into a powerful multi-functional tool in seconds. It allows your operators to select, lock on and utilize attachments quickly and safely from the comfort of the cab, helping you do more and earn more.

Careful distribution of stress loads increases the Z-bar’s tolerance significantly. Improved Z-bar geometry enhances bucket breakout force, operator visibility, loading stability and speed.

LiuGong’s new-generation advanced hydraulic system adapts itself to any job, organizing the mechanical, electrical and hydraulic systems to work in perfect harmony.

Adaptive technology perfectly matches the hydraulic flow with the machine’s operation. Power is only supplied as needed, ensuring superior control of both the boom and the attachment enabling the operator to complete a variety of demanding tasks with precision and efficiency.

Adaptive technology perfectly matches the hydraulic flow with the machine’s operation. Power is only supplied as needed, ensuring superior control of both the boom and the attachment enabling the operator to complete a variety of demanding tasks with precision and efficiency.

Limited-slip differential front axle and conventional rear match themselves to the toughest terrain, automatically delivering power to all four tires and increasing traction for maximized bucket filling performance. Advanced axle engineering increases the resistance to both internal torque loads and the external forces helping to get tough work done easily.

LiuGong wheel loaders excel in adapting to any jobsite conditions. Our new generation ride control, coupled with an automated bucket positioning feature, absorbs shocks and improves ride quality for the operator over any terrain. Importantly, our new ride control significantly prevents material loss and perfectly complements our new buckets which are easier to fill, load and carry, noticeably increasing productivity and earning potential.

COMFORT AND SAFETY.

NO COMPROMISES

Climb into our cabs and you can see that they have been designed by someone who has operated a machine in really tough conditions and who knows the importance of comfort and safety.

For a start, 3-Bar stamped steps with a 10° ergonomic incline and improved anti slip tread make our machines safe and easy to get in and out of. Well-placed door handles, safety rails and anti-slip tape on the upper part of the machine make it easier and safer for operators to enter and exit the cab safely in all weathers and conditions. Superior visibility is essential for safe andproductive work on the jobsite, particularly when working in a confined space or when switching multiple attachments. We’ve risen to the visibility challenge by creating a panoramic view cab with curved front glass and well positioned lift arms to guarantee the operator a clear line of sight to the bucket edge at ground level. Sight lines to all corners of the machine have also been improved to increase safety whilst the optional rear-view camera contributes to an overall visibility improvement of 15%. The controls, including joystick or finger control levers, are where the operator needs them to be. They are easy to see, easy to reach and easy to handle. The multi-adjustable air-suspension seats are comfortable and designed to keep the operator fresh and alert.

The cab protects the operator from noise and vibrations and is well ventilated. It has advanced climate control to handle the changing seasons and is completely sealed to prevent dust from entering the workplace.

Whatever the job, an advanced climate control system with eight all-round vents, creates the perfect working environment in any weather. Easy-to-replace air filters further enhance the operator’s experience eliminating dust and preventing particles from polluting the cab.

We believe in making life easy for the operator which is why we’ve positioned the kick-down and forward/reverse buttons on the joystick. The kick-down function gives the operator finger-tip control enabling him to lower the gear, increase engine torque and maximize bucket breakout force with the minimum of effort.

TOUGH QUALITY

STANDARDS

When it comes to quality, we let our actions to speak for themselves. We follow a rigorous Six Sigma methodology and consistently achieve ISO 9001 standards

DAILY CHECKS AND MAINTENANCE SHOULDN’T BE TOUGH

Simple daily checks and maintenance prolong machine performance but, they can be difficult and time consuming on tough jobsites where time is precious.

Not with our wheel loaders.

The wide opening fiberglass hood gives fast and easy access to the engine and regular service points – that’s good news for operators who want to reduce maintenance time to the minimum.

Not with our wheel loaders.

The wide opening fiberglass hood gives fast and easy access to the engine and regular service points – that’s good news for operators who want to reduce maintenance time to the minimum.

With on board monitoring, the operator can check the machine’s vital signs; oil temperatures and pressure levels, receive service interval alerts and access all the information that contributes to simple maintenance and servicing of the machine, right from his seat.

• Easily visible hydraulic oil level gauge

• Ground accessible, grouped filters

• Easy to reach electronic control box

• Easy to replace A/C filter next to the cab door

• Ground accessible, grouped filters

• Easy to reach electronic control box

• Easy to replace A/C filter next to the cab door

JOBSITE UPTIME AND SUPPORT

Heavyweight credibility might convince you to buy your first machine, but it’s uptime and support and total cost of ownership which will keep you coming back to buy more machines. Having confidence in the machine’s back up and support network is a vital part of the purchasing decision. How do we at LiuGong measure up?

We have an extensive dealer network of over 300 dealers in more than 100 countries. All supported by 13 regional subsidiaries and 17 regional parts depots offering expert training, parts and service support.

Our aim was to maximise uptime by making service and maintenance as convenient as possible. Our design team rose to the challenge delivering service and maintenance layout which is second to none.

Convenience and safety should never be compromised.

The easy to access optional re-fuelling pump is safely stowed behind the bay door.

All filters are located close to the bay doors for safe access and speedy maintenance.

Low level access to DEF tank reduces the need to climb up onto the upper structure.

The easy to access optional re-fuelling pump is safely stowed behind the bay door.

All filters are located close to the bay doors for safe access and speedy maintenance.

Low level access to DEF tank reduces the need to climb up onto the upper structure.

By grouping the greasing points together on the boom base, top of the dipper and slew bearing we make daily maintenance faster and easier

Our red-designed air filter with large ash

capacity now has a 1000-hour maintenance cycle – that’s one job less to think about.

capacity now has a 1000-hour maintenance cycle – that’s one job less to think about.

Our plastic moulded fuel tank increases

fuel capacity and will never rust, preventing filter blockage.

fuel capacity and will never rust, preventing filter blockage.

TOTAL COST OF OWNERSHIP

Jobsite adaptability and uptime & support are two key wheel loader purchasing criteria but ultimately, the machine’s earning potential, its overall life cost and its trade-in value really matter too.

When it comes to total cost of ownership LiuGong has a strong story to tell.

We are committed to reducing your total cost of ownership and increasing your profits. As part of this, LiuGong’s experts will provide targeted advice on everything, from choosing the right machine for your needs to maximizing its efficiency on site.

Our machines deliver everything you need and nothing you don’t. They are expertly engineered NOT over engineered. As a result of having an extensive manufacturing operation right in the heart of Europe, we can offer significantly shorter lead times on a range of models, compared with some manufacturers. In fact, we can deliver selected machines in as little as 4 weeks. The faster you can get a machine – the faster you can get working and earning. Our aim is to get you on to the jobsite fast.

At LiuGong, our aim is to provide you with real, measurable value by giving you everything you need and nothing you don’t. We choose high quality, proven components and parts from world renowned brands and suppliers. These proven components, combined with LiuGong design and manufacturing quality, result in a high quality, competitive machine that is totally fit for purpose.

With the combination of LiuGong design and manufacturing excellence, world class components and comprehensive uptime support, our quality holds its value.

Specification

Download a brochure835H - Stage IV

Maximum operating weight

12852kg

Minimum operating weight

10860kg

Standard bucket

1.9 m³

Gross power

98 kW (133 hp) @ 2200 rpm

Net power

93 kW (125 hp) @ 2200 rpm

Rated load

3000 kg

Total cycle time

9.6 s

Tipping load-full turn

7369 kg

Bucket breakout force

100 kN

Dump clearance, full height discharge

2800 mm

Dump reach, full height discharge

1076 mm

Model

Cummins QSB5.9-C150

Emissions

EU Stage IV

Cooling system

Charge air cooling

Length with bucket down

7115 mm

Width over tires

2300 mm

Cab height

3200 mm

Turning radius, outside of tire

5410 mm

Bucket capacity

1.5-3.0 m³

General Purpose

1.9 m³

Light material

2.5, 3.0 m³

Heavy-rock

1.5 m³