HOME > MACHINES > EXCAVATORS

915FCR

THE BEST MACHINES

ARE DESIGNED

FOR BALANCE,

NOT COMPROMISE...

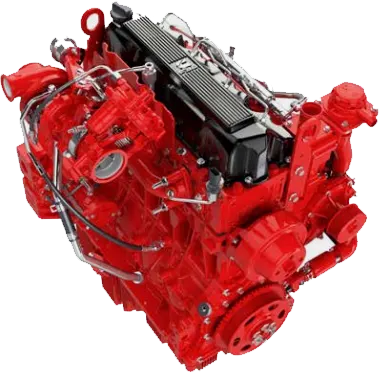

Engine

Cummins B6.7

Net Power

69.5 / 84.5 kW

Operating Weight

15,400 - 17,300kg

Bucket Capacity

0.77m3

THE BEST MACHINES ARE DESIGNED FOR BALANCE, NOT COMPROMISE...

TOUGHNESS & DURABILITY

DESIGNED TO WORK HARDER, FOR LONGER

To build machines that can withstand the hardest conditions takes intelligent design, and attention to detail. We know that a machine is only as strong as its weakest point, so every weld, every joint, every component is scrutinized to ensure it passes our rigorous durability tests. Here’s the proof.

We’ve increased the size of our upper and lower track rollers to reduce the stress by 8% and increase the carrying capacity by 20% respectively.

Our machines may be tough, but with the optional rubber block tracks they’re soft on the surface to avoid unnecessary damage.

100% flaw detection ensures every weld is checked to meet our stringent standards.

Choose from our range of performance and durability enhancing extras such as our easy to fit demolition guards and heavy duty counter-weight.

Finite element analysis proves the load efficiency and toughness of our boom and arm, but we go further to reduce stress by 50%.

POWER AND EFFICIENCY

DESIGNED TO MOVE MORE, FOR LESS...

There’s no need to compromise digging performance to get the highest fuel efficiency because the all New 913FCR and 915FCR gives you both. With greater torque and more power at lower engine speeds you get the power you want and the fuel efficiency you need.

With VGT technology, the 3.8L Four Cylinder Cummins engine delivers 5% extra torque compared to high torque at low engine speeds. VGT enables the engine to maximize its power output whilst creating less noise and using less fuel.

When it comes to efficiency, the 913FCR and 915FCR is smarter than you’d think. Feed Forward control technology matches the engine’s speed to the operator’s command and predicted load to deliver even greater fuel economy.

913FCR features an additional 15kW of engine power, providing extra performance in tougher ground conditions and when using larger attachments.

Engine Auto Idle and Auto Shutdown make every single drop of fuel count. Reducing

unproductive fuel saves you money and helps protect the environment.

unproductive fuel saves you money and helps protect the environment.

Larger displacement slew motor and higher relief pressures allow 7% greater torque to increase cycle times.

The optional dozer blade gives you extra stability and a multitasking capability to keep your site clean and level.

WHY CHOOSE BETWEEN POWER AND EFFICIENCY WHEN YOU CAN HAVE BOTH?

The all new FCR models let you do more, for less cost, and with less environmental impact, don’t settle for anything less

TOUGH MACHINES CAN BE INTELLIGENT TOO

INTELLIGENCE AND CONTROL

DESIGNED TO WORK SMARTER

Smart operators choose smart machines because they know their job is tough enough. When it comes to intelligence and control the all New FCR models may surprise you as they’re packed with smart features to make life easier.

With a choice of 3 Integrated Work Modes each designed to match the engine speed, pump flow and system pressure to your chosen application, it’s easy to find the perfect balance of performance and economy.

The state-of-the-art full electro-hydraulic system from Kawasaki provides lightening fast signals between the joysticks, pumps and valve blocks to deliver pin point precision and maximize available engine power.

With a suite of Smart functions at your fingertips you can control your attachment properties from the comfort of your cab. It’s easy:

Adjustable flow control

Adjustable pressure control

10 attachment settings

Adjustable flow control

Adjustable pressure control

10 attachment settings

We’ve increased the size of our hydraulic pump with 12% greater displacement to increase flow at lower engine speeds and save on fuel.

Two piece boom option increases versatility with 300mm extra digging reach and flat bottom trench depth, plus 600mm increased dump height.

COMFORT AND ERGONOMICS

DESIGNED AROUND THE OPERATOR

Climb into the spacious cab and you’ll know that it has been designed by a team that really knows what its like to be an operator. Talking, listening and observing operators, our design team spend almost as much time in the cab as they do with the CAD. The result? One of the most ergonomic and comfortable cabs you can get.

From the ergonomically positioned non-slip pedals to the multi-functional joysticks, the cab interior represents a masterclass in design.

Every action and movement requires the minimum of effort from the operator.

Every action and movement requires the minimum of effort from the operator.

Every operator is different, so we offer a range of seats and joystick configurations to suit everyone.

Mechanical suspension standard seat

Comfort level, air suspension seat with adjustable lumbar support.

Luxury level, heated air suspension seat with adjustable lumbar and premium padding.

Mechanical suspension standard seat

Comfort level, air suspension seat with adjustable lumbar support.

Luxury level, heated air suspension seat with adjustable lumbar and premium padding.

We’ve designed the operator interface to be even more intuitive and easy to use. The large 8-inch LCD colour screen can be controlled via touchscreen or by a fingertip navigational control dial conveniently sited in the armrest control panel.

We never forget that a machine is not just a tool, it’s your place for many hours a day (and night). So, we’ve remembered all the little things that make it feel like home.

Large storage box and rack

Drinks holder

Phone holder with 12V charging, USB and

AUX ports

Large storage box and rack

Drinks holder

Phone holder with 12V charging, USB and

AUX ports

The cab is packed with comfort-enhancing technology; the NVH design reduces wind resistance and noise, and the silicone oil shock absorbers and CAE analysis all add up to the calmest and quietest operator experience possible.

NO MATTER WHAT YOU DO, YOU’VE GOT TO TRUST YOUR MACHINE 100%

SAFETY AND VISIBILITY

SAFER ALL-ROUND

Being protected in the cab is important, but accident research shows us that most accidents occur outside of the machine. We’ve taken the challenge to make our machines even safer to be around.

The driver protection system delivers even greater protection to the front and top of the cab and protects the operator from falling rocks and debris. The front screen has a hinge design making cleaning and maintenance easier.

The new 0.5m wide stepped boarding channel with non-slip treadplates makes getting on and off the machine safer Optional guard rails or integral fences on the left and right sides of the upper platform increase safety and can be folded down for easy transportation.

The ground level emergency stop switch is fitted as standard.

With 360 degree camera as standard in Europe, you can get an uninterrupted panoramic view around the machine at all angles from the large LCD screen.

With a 1.52m tail swing, our new FCR models can work in the tightest of spaces.

Shorter tail swing reduces potential collision damage.

Creates a safer environment for those working around the machine.

Shorter tail swing reduces potential collision damage.

Creates a safer environment for those working around the machine.

No need to climb on the machine, all the daily maintenance points, including the oil level check point are easily accessible from the ground.

LED work light for better night visibility is fitted as standard.

MAINTENANCE AND UPTIME

EASY TO OWN AND EASY TO MAINTAIN

We understand that when your machine’s not working, it’s not earning. To maximize your productive hours, we’ve made the All New FCR models are even easier to maintain, helping you make every productive second count.

Maintenance should be simple so to save you time, all engine oil filter replacement cycles have been synchronized.

Our aim was to maximise uptime by making service and maintenance as convenient as possible. Our design team rose to the challenge delivering service and maintenance layout which is second to none.

Convenience and safety should never be compromised.

The easy to access optional re-fuelling pump is safely stowed behind the bay door.

All filters are located close to the bay doors for safe access and speedy maintenance.

Low level access to DEF tank reduces the need to climb up onto the upper structure.

The easy to access optional re-fuelling pump is safely stowed behind the bay door.

All filters are located close to the bay doors for safe access and speedy maintenance.

Low level access to DEF tank reduces the need to climb up onto the upper structure.

By grouping the greasing points together on the boom base, top of the dipper and slew bearing we make daily maintenance faster and easier

Our red-designed air filter with large ash

capacity now has a 1000-hour maintenance cycle – that’s one job less to think about.

capacity now has a 1000-hour maintenance cycle – that’s one job less to think about.

Our plastic moulded fuel tank increases

fuel capacity and will never rust, preventing filter blockage.

fuel capacity and will never rust, preventing filter blockage.

Specification

Download a brochure915FCR - STAGE V

Maximum operating weight

17200kg

Minimum operating weight

15400kg

Engine power

84.5 kW

Bucket capacity

0,77m³

Maximum travel speed (High)

4.9 km/h

Maximum travel speed (Low)

2.9 km/h

Maximum swing speed

11.3 rpm

Arm breakout force

64.9 kN

Arm breakout force Power boost

70 kN

Bucket breakout force

89.8 kN

Bucket breakout force Power boost

96.9 kN

Shipping length

7,335 mm

Shipping width

-

Shipping height

2980 mm

Track shoe width (std)

500 mm

Boom

4600 mm

Arm

2900 / 2500 mm

Digging reach

8365 / 8670 mm

Digging reach on ground

8235 / 8760 mm

Digging depth

5940 / 5515 mm

Vertical wall digging depth

5030 / 5445 mm

Cutting height

9640 / 9040 mm

Dumping height

6510 / 7090 mm

Minimum front swing radius

2470 / 2400 mm

Model

Cummins

Emission

Stage V

System maximum flow

2×117 L/min (2×30,9 gal/min)

System pressure

34.3 MPa